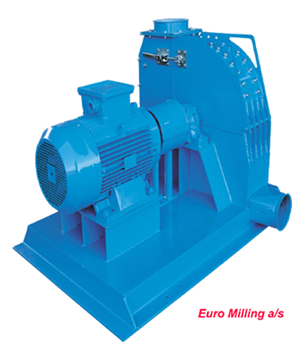

Specifications.

| Motor | kW | 15-30 |

|---|---|---|

| Sold areal | m2 | 0,2 |

| Hamre | 2,5 | 88 |

| Hamre | 8,0 | 44 |

| Kapacitet* | tons/t | 1.0 - 2.5 |

| Støjniveau | dB(A) | 85 |

| Vægt med motor | kg | 420 |

* = Kapaciteten afhænger af materiale / sold- og motor størrelse

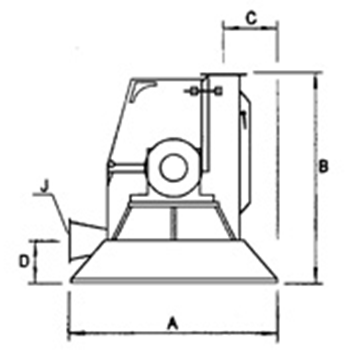

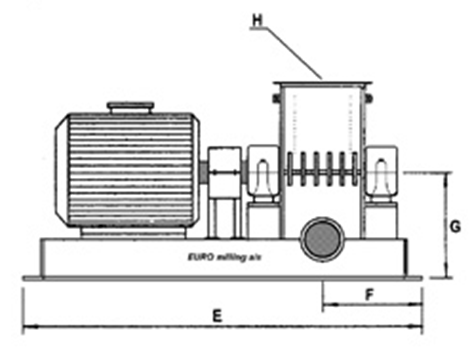

| A | B | C | D | E | F | G | H | J | |

|---|---|---|---|---|---|---|---|---|---|

| mm. | 860 | 810 | 175 | 100 | 1350 | 800 | 445 | 200x205 | ø150 |